From 5 manual packaging employees to 1 machine operator

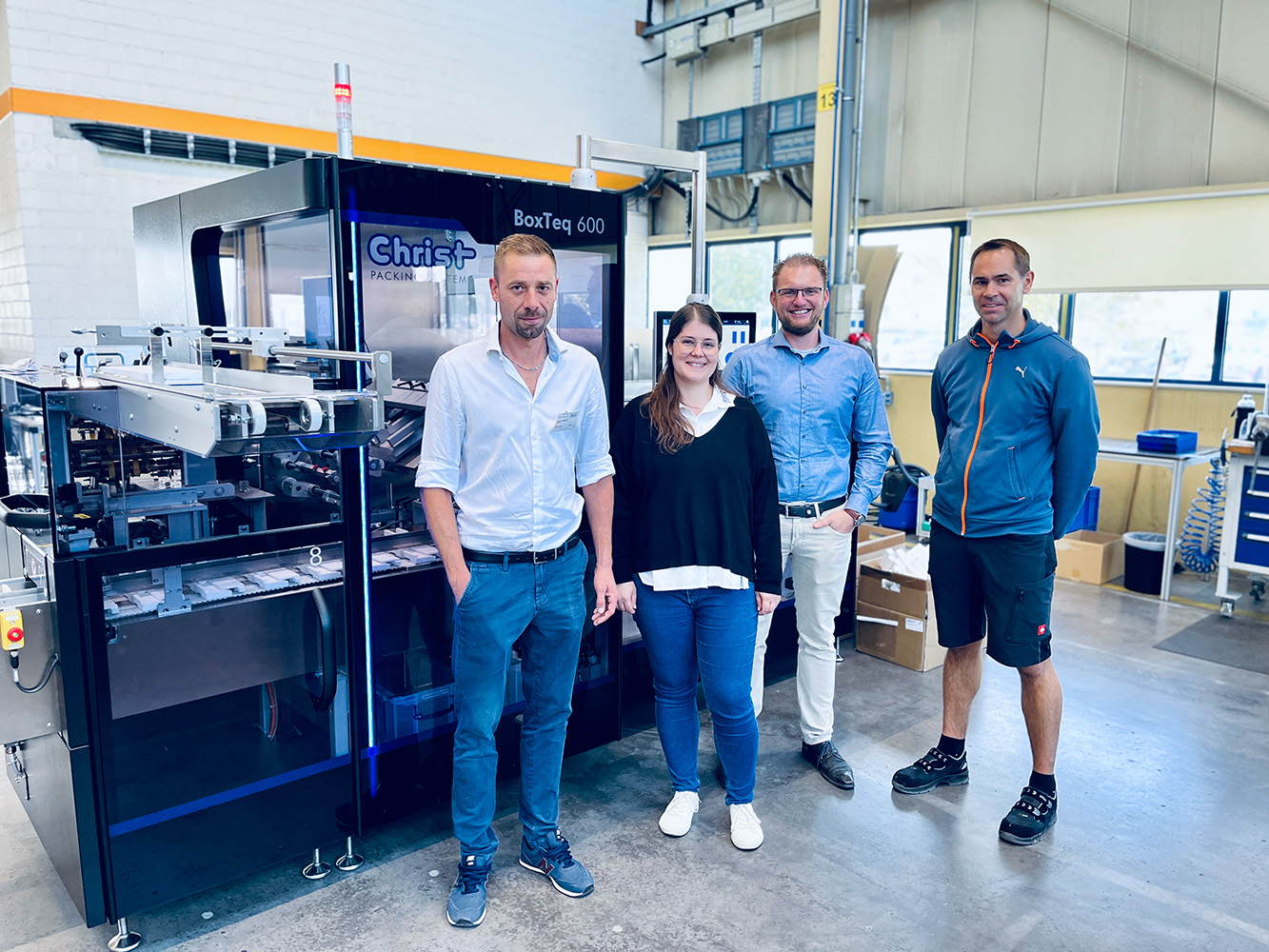

Successful FAT with OPTOSOL for the very first BoxTeq 600 cartoner in its new design

Automation at its best.

OPTOSOL Chemische Produkte GmbH is a German-based producer of care products for contact lenses, and specializes in contract manufacturing of sterile solutions & liquid medical products.

With the aim to automate the manual packaging of nasal sprays into folding boxes, OPTOSOL turned to Christ for a fully-automatic cartoner. As CMO, fast machine delivery as well as cost effectiveness were important criteria when choosing a machine supplier. Christ was able to offer both.

With the BoxTeq cartoner, OPTOSOL goes from 5 employees formerly packing the nasal sprays by hand, to 1 employee feeding the machine, thus freeing up human resources for higher-value tasks.

Project key points:

- 70 nasal spray bottles per minute

- Manuel feeding of spray bottles

- Feeding of pre-folded leaflet

- Tuck-in flap on both sides

- 2 ejection possibilities

Highlights of the BoxTeq 600 cartoner:

- Flexible: fast, simple, largely tool-free format changeovers

- Sustainable: low-maintenance components and long machine life

- Gentle product handling: optimum interaction of all movements via servo motors

- Expandable: serialization can be added, all common camera systems can be integrated

- Accessible: swivelling electrical cabinet and ergonomic service position of the carton magazine

- User-friendly: long autonomous machine run due to large carton magazine (up to 750 carton blanks)

We would like to thank our team for the excellent work, Mr. Alfred B. Hefft for the successful FAT, and we are looking forward to the installation of the BoxTeq 600 in Miesbach, Bavaria!